Scaffolds - Supported

Scaffolds are temporary structures that consist of one or more elevated platforms used where work cannot be done on or from the ground, from a building or other permanent structure without hazard to the workers. Selection of the wrong type of scaffold, improper design, erection, transport, or dismantling of the structure, as well as substandard work practice may lead to serious accidents. The hazards associated with scaffolding are:

- Failure of scaffold or supporting system

- Falling from heights

- Instability

- Collapse

- Falling object

To prevent such occurrences, the constructors and employers have the responsibility to ensure that all activities related to selection, erection and dismantling of scaffolding are conducted by competent worker who have the knowledge, expertise and training required to correctly select, erect or dismantle a scaffold. See the topic Scaffold – Erection for more details.

Every scaffold must be designed and constructed meet or exceed support or resist requirements and must not be loaded in excess of the load it was designed to carry. . A professional engineer must verify and certify the results of the test and corresponding rated load.

Scaffolds must be constructed of suitable structural materials. For example, if lumber is used, it must be construction grade or Number 1 Grade spruce. Other requirements are listed

Scaffolds must be designed by a professional engineer in the following situations:

- Supported scaffolds exceeding:

- Suspended scaffolds that consist of more than one platform

- Suspended platforms that together with its components weights more than 525 kg must.

- Multi-point suspended work platforms

Scaffolds can be grouped in two main types: supported and suspended. This topic discusses supported scaffolds.

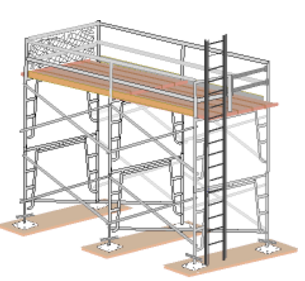

Supported scaffolds are scaffolds supported from the ground by rigid elements such as outrigger beams, poles, legs, base plates, sills and posts.

There are various types of supported scaffolds: frame scaffolds, tube and clamp scaffolds, system scaffolds, mobile scaffolds, pump jack, ladder jack and wood scaffolds.

General structural requirements for scaffolds and scaffold platforms

- A scaffold must:

- Support or resist to

- two times the maximum load or force to which it is likely to be subjected, without exceeding the allowable unit stresses for the materials of which it is made;

- four times the maximum load or force to which it is likely to be subjected without overturning

Resist three times the maximum load or force to which it is likely to be subjected without causing the failure of any component, if the scaffold has structural components whose capacity can only be determined by testing.

Be constructed of adequate structural materials

Have uprights braced diagonally in the horizontal and vertical planes to prevent lateral (side to side) movement; that the horizontal members are adequately secured, and do not have splices between the points of support; footings, sills, or supports that are sound, rigid, and capable of supporting at least two times the maximum load without settlement or deformation; fittings and gear, including base plates or wheels, installed according to manufacturer’s instructions, connecting devices between the frames that engages both tension and compression appropriately, safety catches on all hooks, and vertical intervals are used and adequately secured which do not exceed three times of the specified dimension

The rated loads for the scaffold must be stated in the design drawings.

A scaffold platform must:

- Be designed and built to support and resist all loads and forces to which it is likely to be subjected and at least 2.4 kilonewtons per square metre

- Be at least 460 mm wide; have the planks laid tightly if its height is 2.4 metre or more; and have guardrails if higher than 2.4 metres

- Have all openings guarded

- Have safe means of access (ladders, stairs) if they are above ground level and cannot be moved to give access to a floor, roof or ground level

- Have each component secured against slipping from its support

- Be made of components each capable of supporting at least 2.2 kilonewtons .

Wood platforms must:

- Have the planks made from Number 1 Grade spruce and bear legible identification

- Have the planks of at least forty-eight millimetres thick by 248 millimetres wide

The wood planks must cleated or secured by other means against slipping, must be arrange so that their length does not exceed 2.1 metres, and must go over their support at least 150 millimetres but less than 300 millimetres.

. For example, a frame scaffold is supported scaffold composed of standard metal frames of various widths, heights and load capacities. Widely used due to fact that they are erected and dismantled relatively easy.

If masonry units are placed on platforms supported by tubular metal frames, each frame leg of the scaffold must have a minimum working load of (a) twenty-two kilonewtons for standard frames, and (b) 16.7 kilonewtons for walk-through frames.

The stringers of prefabricated stairs erected inside a tower formed by scaffold frame sections must have a maximum slope of 60 degrees from the horizontal.

Mobile scaffolds include portable frame or tube and clamp scaffolds set on castor wheels or tires equipped with a breaking device on each wheel. The scaffold must be equipped with guy wires or outriggers if the height of the platform exceeds three times lateral dimension of the scaffold measured at the base or between outriggers (if used).

Construction Projects

O. Reg. 213/91

Part II GENERAL CONSTRUCTION

Section 77

77. (1) No work shall be performed in a building or structure with stairs unless the stairs meet the requirements of this section.

(2) Stairs shall have,

(a) a clear width of at least 500 millimetres;

(b) treads and risers of uniform width, length and height;

(c) subject to subsection (3), stringers with a maximum slope of 50 degrees from the horizontal;

(d) landings that are less than 4.5 metres apart measured vertically;

(e) a securely fastened and supported wooden handrail on the open sides of each flight; and

(f) a guardrail on the open side of each landing.

(3) The stringers of prefabricated stairs erected inside a tower formed by scaffold frame sections shall have a maximum slope of 60 degrees from the horizontal.

(4) A wooden handrail shall measure thirty-eight millimetres by eighty-nine millimetres and shall be free of loose knots, sharp edges, splinters and shakes.

(5) Skeleton steel stairs shall have temporary wooden treads securely fastened in place that are made of suitable planking extending the full width and breadth of the stairs and landings.

Ladders

Section 125

125. (1) Where work cannot be done on or from the ground or from a building or other permanent structure without hazard to workers, a worker shall be provided with a scaffold, a suspended work platform, a boatswain’s chair or a multipoint suspended work platform that meets the requirements of this Regulation.

(2) A worker who is on or under a scaffold, a suspended work platform system or a multi-point suspended work platform while it is being erected, altered or dismantled shall be on a part of the scaffold, suspended work platform system or multipoint suspended work platform that meets the requirements of this Regulation.

[O. Reg. 242/16, s. 9]

Scaffolds and Work Platforms

Section 126

126. (1) Every scaffold shall be designed and constructed to support or resist,

(a) two times the maximum load or force to which it is likely to be subjected, without exceeding the allowable unit stresses for the materials of which it is made; and

(b) four times the maximum load or force to which it is likely to be subjected without overturning.

(2) Despite clause (1)(a), a scaffold with structural components whose capacity can only be determined by testing shall be designed and constructed to support or resist three times the maximum load or force to which it is likely to be subjected without causing the failure of any component.

(3) No scaffold shall be loaded in excess of the load that it is designed and constructed to bear.

Section 127

127. (1) The failure load of a scaffold which consists of structural components whose capacity cannot be determined by testing shall be established by testing the components in a manner that simulates the actual loading conditions for which each of the components is fabricated.

(2) A professional engineer shall verify and certify the results of a test and the corresponding rated load of the scaffold.

(3) The constructor shall make available to an inspector upon request a copy of the certification by the professional engineer.

Section 128

128. (1) Every scaffold,

(a) shall have uprights braced diagonally in the horizontal and vertical planes to prevent lateral movement;

(b) shall have horizontal members that are adequately secured to prevent lateral movement and that do not have splices between the points of support;

(c) shall have footings, sills or supports that are sound, rigid and capable of supporting at least two times the maximum load to which the scaffold may be subjected without settlement or deformation that may affect the stability of the scaffold;

(d) shall have all fittings and gear, including base plates or wheels, installed in accordance with the manufacturer's instructions;

(e) shall have connecting devices between frames that provide positive engagement in tension and compression;

(f) shall have safety catches on all hooks; and

(g) shall be adequately secured at vertical intervals not exceeding three times the least lateral dimension of the scaffold, measured at the base, to prevent lateral movement.

(2) A scaffold shall be constructed of suitable structural materials and, if lumber is used, it shall be construction grade or Number 1 Grade spruce.

(3) A scaffold mounted on pneumatic tires shall not be supported by the pneumatic tires while the scaffold is being erected, used or dismantled.

(4) If tubular metal frames are used to support masonry units on a scaffold platform, each frame leg shall have a minimum working load of,

(a) twenty-two kilonewtons for standard frames; and

(b) 16.7 kilonewtons for walk-through frames.

Section 129

129. (1) A scaffold mounted on castors or wheels,

(a) shall be equipped with a suitable braking device on each castor or wheel; and

(b) shall have the brakes applied when a worker is on the scaffold.

(2) A scaffold mounted on castors or wheels shall be equipped with guy wires or outriggers to prevent its overturning if the height of the scaffold platform exceeds three times the least lateral dimension of the scaffold,

(a) measured at the base of the scaffold; or

(b) if outriggers are used, measured between the outriggers.

(3) No scaffold mounted on castors or wheels that has a scaffold platform more than 2.4 metres above the base shall be moved when a worker is on it unless,

(a) the worker is wearing a full body harness as part of a fall arrest system attached to a fixed support; and

(b) the scaffold is being moved on a firm level surface.

Section 130

130. (1) A scaffold shall be designed by a professional engineer and shall be erected in accordance with the design if the scaffold exceeds,

(a) fifteen metres in height above its base support; or

(b) ten metres in height above its base support if the scaffold is constructed of a tube and clamp system.

(2) Design drawings for a scaffold shall set out erection instructions and the rated loads for the scaffold.

(3) A professional engineer or a competent worker designated by the supervisor of the project shall inspect the scaffold before it is used to ensure that it is erected in accordance with the design drawings.

(4) The person carrying out an inspection shall state in writing whether the scaffold is erected in accordance with the design drawings.

(5) The constructor shall keep at a project the design drawings and the written statement for a scaffold while the scaffold is erected.

[O. Reg. 85/04, s. 12]

Section 134

134. (1) Every scaffold platform and other work platform shall be designed, constructed and maintained to support or resist, without exceeding the allowable unit stresses for the materials of which it is constructed,

(a) all loads and forces to which it is likely to be subjected; and

(b) at least 2.4 kilonewtons per square metre.

(2) Each component of a scaffold platform or other work platform shall be capable of supporting a load of at least 2.2 kilonewtons without exceeding the allowable unit stress for each material used.

(3) No scaffold platform or other work platform shall be loaded in excess of the load that it is designed and constructed to bear.

Section 135

135. (1) A scaffold platform or other work platform,

(a) shall be at least 460 millimetres wide;

(b) if it is 2.4 metres or more above a floor, roof or other surface, consist of planks laid tightly side by side for the full width of the scaffold;

(c) shall be provided with a guardrail as required by section 26.3;

(d) shall be provided with a means of access as required by section 70;

(e) shall not have any unguarded openings; and

(f) shall have each component secured against slipping from its supports.

(2) A scaffold platform or other work platform made of sawn lumber planks shall have planks of number 1 grade spruce that do not have any defect affecting their load-carrying capacity and,

(a) that bear a legible grade identification stamp or are permanently identified as being number 1 grade spruce;

(b) that are at least forty-eight millimetres thick by 248 millimetres wide;

(c) that are arranged so that their span does not exceed 2.1 metres;

(d) that overhang their supports by not less than 150 millimetres and not more than 300 millimetres; and

(e) that are cleated or otherwise secured against slipping.

[O. Reg. 527/00, s. 4]

Section 139

139. (1) An employer shall ensure that, prior to the first use of a suspended work platform system at a project, the entire system, including its suspension lines, has been inspected, tested and maintained in accordance with this Regulation, the manufacturer’s instructions, and clause 11 (Inspection and Testing) and Clause 12 (Maintenance) of CSA Standard Z271-10 .

(2) The employer shall ensure that the inspection, testing and maintenance referred to in subsection (1) is completed by,

(a) a competent worker; or

(b) if the CSA Standard Z271-10 requires the inspection or test be performed by a person with specific qualifications, such person.

[O. Reg. 85/04, s. 14; 242/16, s. 11]